Features of miMaintenance

- Maintenance by usage

- Automated machine expertise

- Condition monitoring test (CMT)

- Reporting

- Complement to preventive maintenance

- Support to maintenance planning through predictions

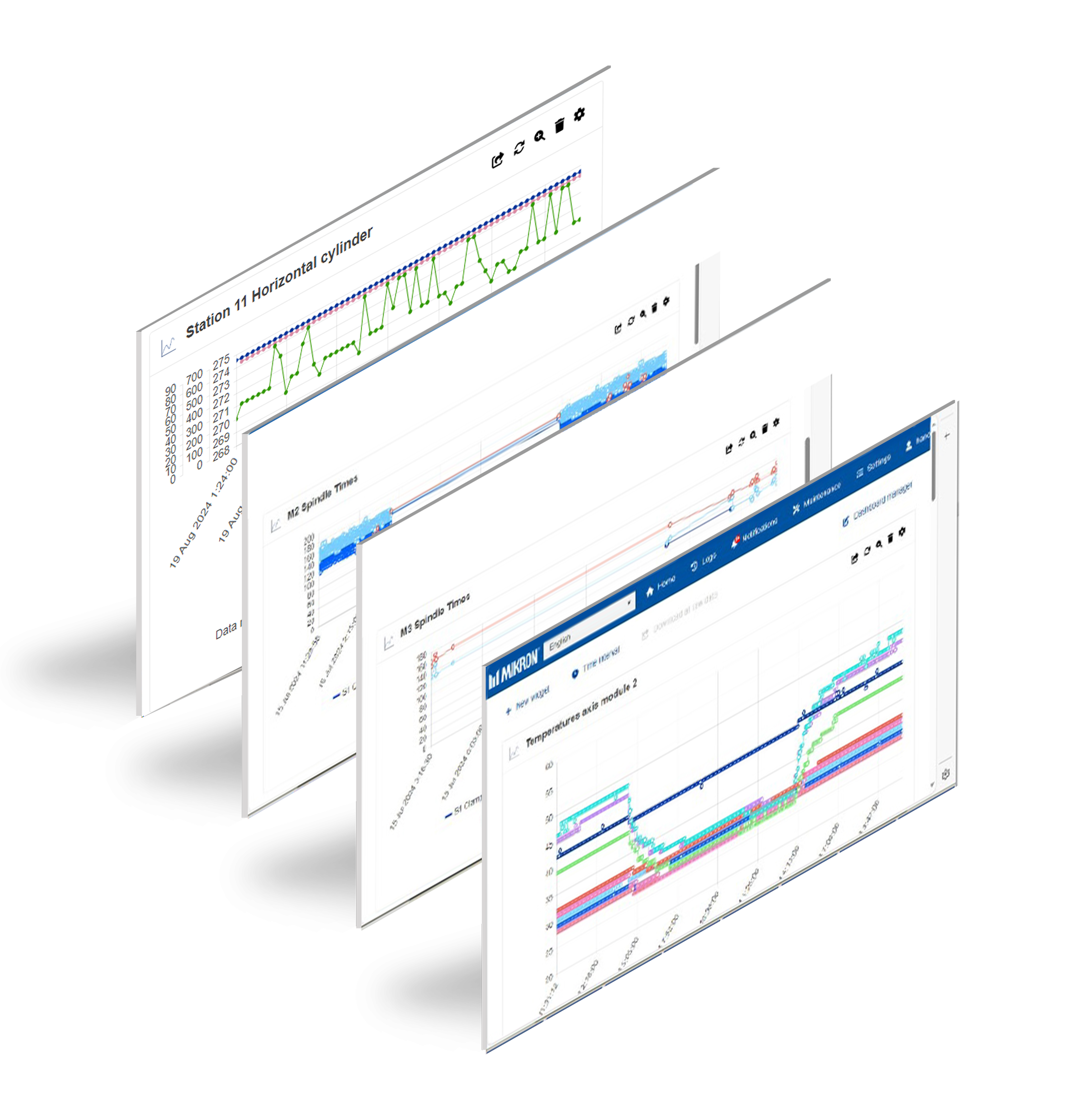

An AI integrated maintenance tool running on Mikron software which enables preventive tasks management and predict machine components failures through advanced algorithms.

A conditions monitoring application to tracks periodically the machine status evolution feeding the predictive analysis.

Kundenbetreuung

Schweiz, Agno

Mikron Switzerland AG, Agno Division Machining

Via Ginnasio 17

6982 Agno

Telefon +41 91 610 61 61

Fax +41 91 610 66 81

service.mag@mikron.com

Bürozeiten: 08.00 – 17.30

Kundenbetreuung

Germany, Rottweil

Mikron Germany GmbH

Berner Feld 71

78628 Rottweil

Telefon +49 741 5380 200

Fax +49 741 5380 380

service.mro@mikron.com

Bürozeiten: 07.30 – 17.00

Kundenbetreuung

USA, Monroe

Mikron Corp. Monroe

200 Main Street

P.O. Box 268

USA-Monroe, CT 06468

Telefon +1 203 261 31 00

Fax +1 203 268 47 52

service.mmo@mikron.com

Bürozeiten: 7.30am-5.00pm EST

Kundenbetreuung

China, Shanghai

Mikron Industrial Equipment (Shanghai) Co., Ltd - China

Building 4, No.2033 Husong Road

Songjiang District, Shanghai, China

Postal Code: 201601

Telefon +86 1592 1577 050

services.mm.msh@mikron.com

Kundenbetreuung

USA, Monroe

24h Service line

Outside office hours

Problem reports 24 h, 7 days a week

Telefon +41 91 610 63 26

Help us to assist you quickly by having the following information ready: Checklist (PDF)