Machining solutions for the consumer goods industry

Are you looking for consumer goods machining solutions that can help you optimize your production process and enhance your product quality?

Look no further than Mikron’s advanced machining systems. Designed specifically for consumer goods manufacturers, they address the industry's most demanding challenges, including:

- High-precision machining for a wide range of materials, shapes, and sizes in consumer goods manufacturing.

- Optimized production speed and efficiency while ensuring superior precision and quality

- Customization capabilities to meet specific design and aesthetic requirements

- Scalability for high-volume production of consumer goods, ensuring cost-effectiveness.

Integration of new materials and machining technologies to enhance performance and functionality.

High-Precision Consumer Goods Machining Solutions

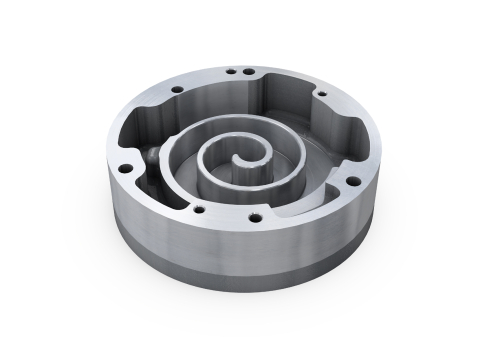

Our cutting-edge consumer goods machining solutions deliver high output rates of up to 22,000 pieces/hour with optimal process efficiency, achieved through 6 to 24 stations depending on your manufacturing needs. These systems are also equipped with precise deburring capabilities that minimize the risk of damage or malfunction to your workpieces.

Moreover, our machining solutions are designed to machine entire parts in a single operating cycle, enhancing efficiency and helping you reach your production goals faster.

Specialized Solutions for the Consumer Goods Industry

Mikron specializes in machining solutions for the consumer goods industry, including:

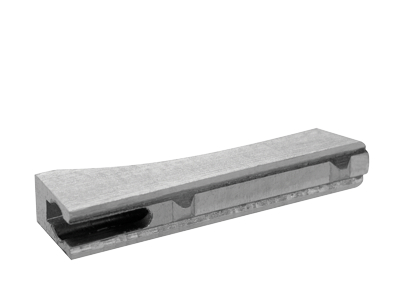

- Watch manufacturing – High-precision micro-machining for watch components.

- Eyewear production – Advanced machining for durable, stylish frames.

- Bicycle parts – Precision machining for lightweight, high-performance components.

- Refrigeration components – Efficient machining for durable, energy-efficient parts.

Discover how Mikron’s consumer goods machining solutions can help you achieve higher efficiency, precision, and scalability. Contact us today to discuss your specific manufacturing needs!