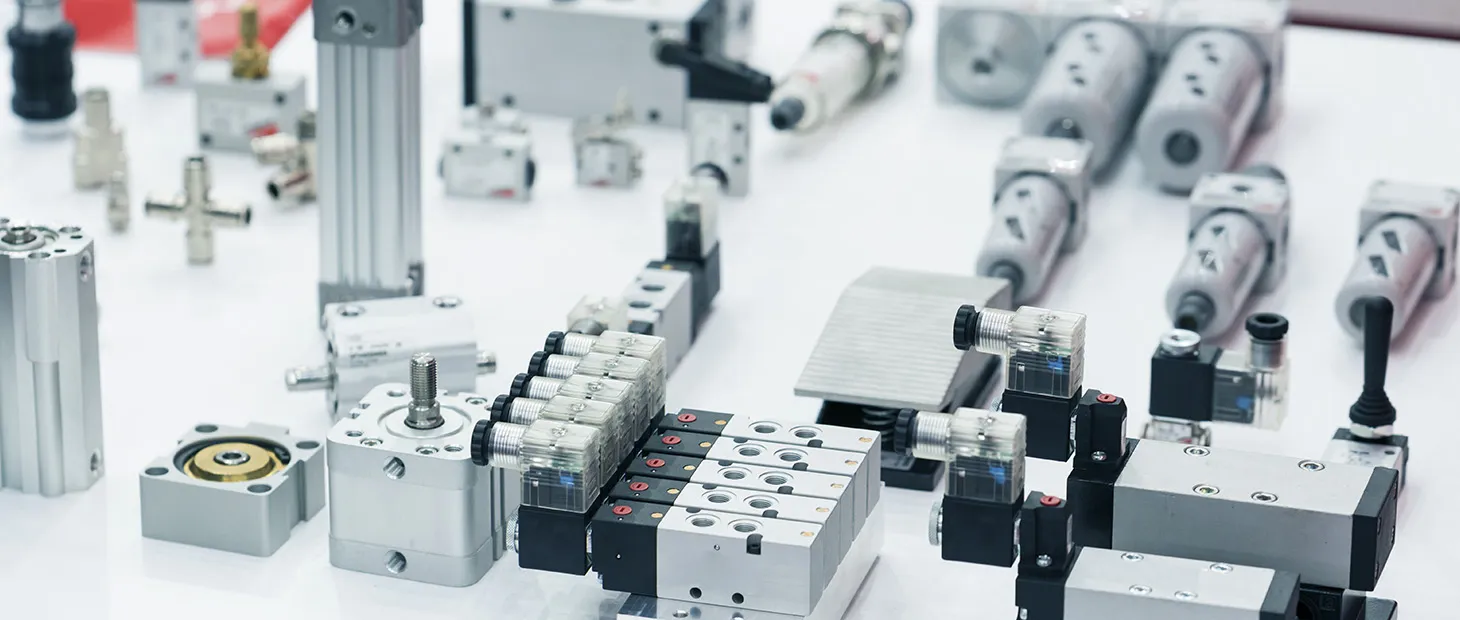

Hydraulic & Pneumatic Machining

Your machines must be everything: economical, faster, and highly precise. Our high-performance machining systems support the production of top-quality hydraulic and pneumatic components, ensuring both efficiency and cost-effectiveness.

These advanced hydraulic and pneumatic machining systems perform critical operations such as drilling, milling, turning, grooving, threading and deburring - all in a single process. This flexibility enables the production of various hydraulic and pneumatic components at maximum capacity.